Pumps & Pumping Systems

Fabrication & Assembly

Supply & Installation

Testing & Commissioning

Maintenance & Repair

Audit & Retrofit

Fabrication & Assembly – Booster Set

A system consisting of two or more number of pumps mounted on a common sturdy base frame complete with manifolds, valves and control panel ready to be connected to the piping network to provide adequate pressure and flow.

We fabricate manifolds, base frame and control panels inhouse and assemble them together with valves and pumps to work as per customer requirement.

Various configuration are possible for booster sets, most common configuration is run and standby using Inline Vertical Multistage or end suction type pumps.

Supply & Installation

We provide optimum selection for the pump to suit system demand requirements.

The pumps are to be installed with other accessories properly to connect to the network of water supply . To enhance the pump life and avoid early wear and tear it is important to have proper installation.

Our team is equipped and ready to provide a good installation of pump and pump systems

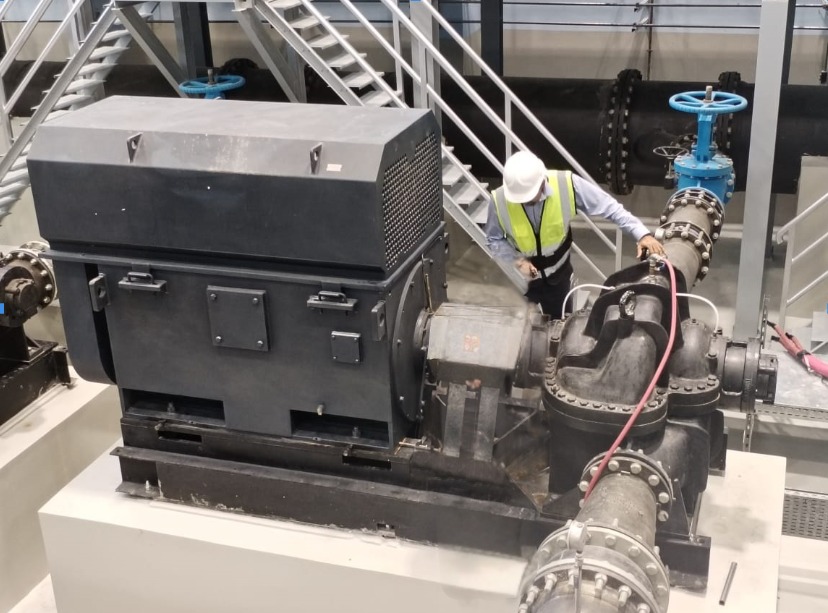

Testing & Commissioning

Pump testing and commissioning are critical steps to ensure that pump system is installed correctly and operates efficiently

Testing of pump will verify that the pump and its components are functioning correctly before it is put into full operation

Pump commissioning is to put the pump in operation and to check that it satisfy the design requirement.

Our team conducts the testing and commissioning with due diligence and provides proper documentation for the satisfaction of consultant and client.

Maintenance & Repair

To ensure long term reliability and efficiency of pumping system operations, regular maintenance are required to avoid unexpected failures.

Monitoring the pump system in operation will help to identify and avoid major failures. Early intervention and repair of wearing pump parts will make sure to keep the system up and running efficiently for a long time.

Our Maintenance & Repair team keeps the check on pump failure and provide breakdown repair of pumps onsite as well as inhouse.

Audit & Retrofit

Pump Audit is a study to evaluate the pumping system effectiveness, performance and reliability. It involves examining pump system installation, operation, maintenance and energy use. This helps to identify the gaps and areas of improvement to enhance the operational efficiency of the system.

Pump Retrofit involves upgrading existing pump system to improve the performance, efficiency and reliability. It include replacing worn out parts or incorporating new technology. It is cost effective alternative to replacing the entire pump system.

Our pump Audit & Retrofit team can offer to evaluate the pump system inefficacies and suggest modifications to have energy efficient pumping system.